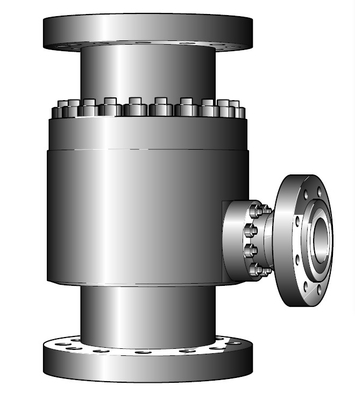

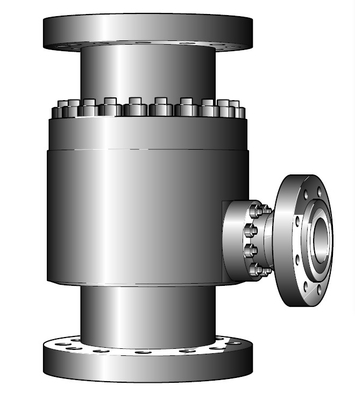

GALLERY

PRODUCT DESCRIPTION

API 6D Automatic Recirculation Valve For Chemical Industry

An API 6D Automatic Recirculation Valve is a kind of pump protection device. It automatically protects the centrifugal pump when a pump body occurs cavitation damage or unstable (especially conveying hot water at low load operation). Once pump flow is lower than the preset flow, bypass can completely open to ensure the minimum required flow pump. Even running fully closed, the name of the main flow is zero, the minimum flow can also discharge from the bypass.

Applications Of Automatic Recirculation Valve

Chemical industry

Petrochemical industry

Steel factory

Fire protection system

Traditional power plant

Paper-making industry

Shipment/shipping

environmental protection industry

1. Main Flow Only – Bypass Closed

When the process associated with the pump is in the normal operating condition, the main line is open. The pressure created from the media flow is sufficient to compress the spring in the check valve disc and lift it from its seat to the fully open position. As the connected disc stem rises, the bypass exit in the stem funnel is moved against the valve body and the bypass system is closed. The recirculation flow is blocked, thus eliminating wasted energy. This is illustrated in Figure 1. The bypass flow is therefore inversely proportional to the main pump flow. When the check valve is fully opened, the bypass is fully closed.

2. Combined Flow

As the flow requested by the process is reduced, the pressure on the disc spring is lowered and the disc moves towards its seat. The check valve part of the automatic recirculation valve moves first to a partially open position (illustrated in figure 2). In this position there is partial flow to the outlet and a minimum flow to the bypass is maintained.

3. No Main Flow – Bypass Only

When no product is required by the process, the valve disc returns to its seated position. There is insufficient flow to compress the spring and allow the disc to rise. In this position, the curved part of the hollow stem is now flush with the entrance to the bypass funnel. A predefined minimum flow can now move from the pump through the bypass section and be recirculated to the front end of the pump. The centrifugal pump is protected from overheating or cavitation.

Leave your message