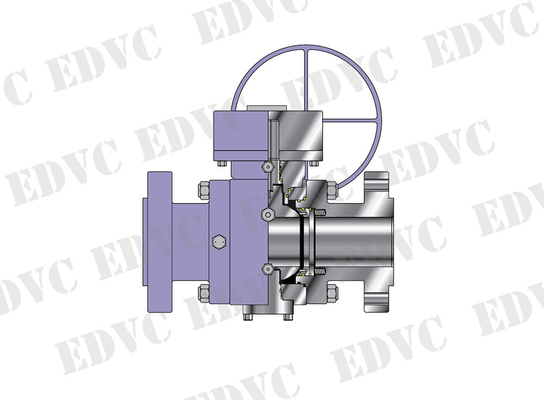

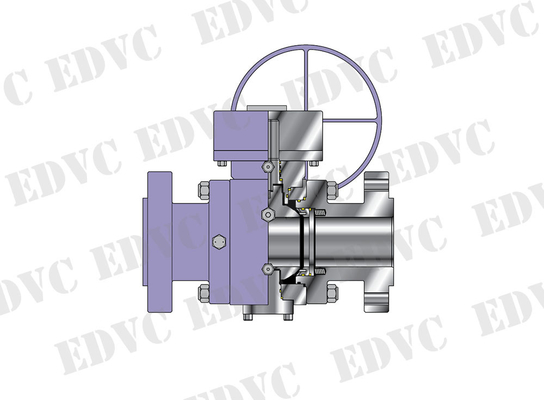

GALLERY

PRODUCT DESCRIPTION

Full Bore Stainless Steel Side Entry Ball Valve

MAIN FEATURES:

Seat of metal to metal ball valves have special protection and tight shut-off design to be applied to some poor conditions, such as high- temperate, high pressure and abrasive mediums, to fully solve the problem of inner leakage and outer leakage, and ensure reliable sealing with zero leakage.

Product Range:

- Body material: carbon steel, stainless steel, alloy steel, dual-phase steel

- Nominal diameter:2"~32"

- Pressure range:Class150~2500

- End connection: RF, RTJ, BW

- Working temperature:-29℃~+560℃

- Operation : wrench, worm gear, electric, pneumatic actuator, gas over oil actuator, electro-hydraulic actuator , etc.

Design Features:

Advanced rocket-spraying process ensures that sealing is realiable under all temperatures — pressures. With hydrogen used as fuel, this process has been applied to the sealing faces of the ball and the valve seats;

Double block and bleed;

Cavity pressure self relief;

Blowout-proof stem;

Seats are Tungsten Carbide HVOF(High Velocity Oxy Fuel) or overlay cladding coated with metal to metal contact between seats and ball, with metal to metal seat sealing characteristics, and it can clean dirt at surface of the gates.

Hardness of coating surface: up to HRC68~ 72;

Bonding strength of coating: ≥10000Psi;

Thickness of coating: 0.3 - 0.5 mm;

The precise “one-to-one” grinding process ensures the precise “one-to-one” grinding between the ball and the valve seat;

Leave your message