GALLERY

PRODUCT DESCRIPTION

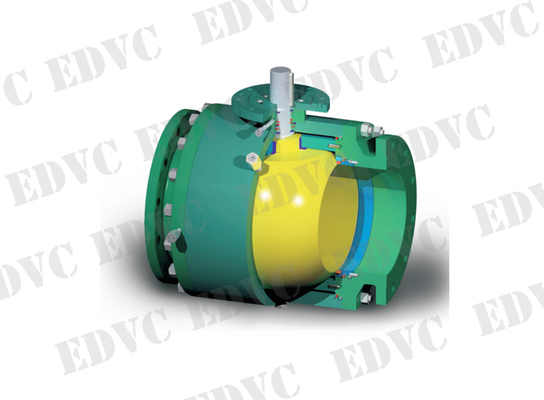

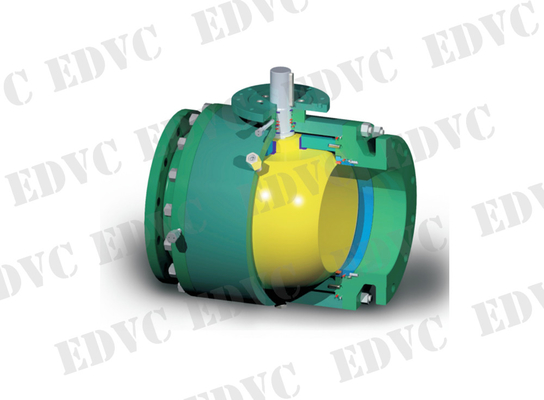

Electric Actuator Split Body Side Entry Ball Valve

EDVC Side entry ball valve contains 3 main series: 1.cast steel two-piece design, 2.forged steel three-piece design and 3. top entry uni-body design, all designed conform to API 6D and fire safe test are satisfied to BS 6755 and API 6FA. They are available in size from 2 to 48 Wide range of body and trim material is available for service temperature from -46 C to 200C and pressure rating from ANSI class 150 to 1500 or for sour service to NACE Mr0175.

Body type design

●Two piece , split body design

●Three piece , forged steel design

●Side Entry Design, Top Entry Design.

Standards

● Design standard: API 6D, EN13942, ISO-14313. ASME B16.34

● Face To Face Dimension: API 6D, EN 558-1, EN 12982, and ASME B16.10

● manual Operators

● Gearbox Operated

● Electric Actuators

● Pneumatic Actuators

● Gas Over Oil Actuators

● Electric-hydraulic actuator

BLOW-OUT PROOF STEM DESIGN

The stem is designed separated from ball, and designed as T slot shape at the bottom side, and gland flange will prevent the stem blow out in case of any abnormal cavity pressure increase.

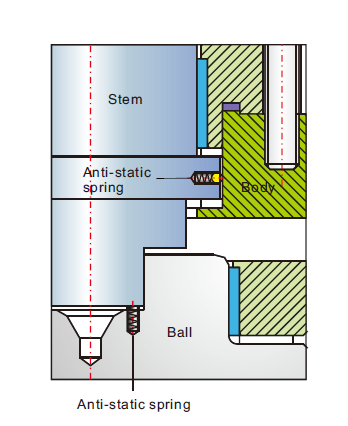

ANTI-STATIC DEVICE

The electrical conductance continuity connect the ball, stem and body, it can avoid the any fire or explosion caused by the static that might be produced and accumulated by friction between the ball and seat ring during valve open or close.

FIRE SAFE DESIGN

External leakage prevention

In normal condition, leakage through the valve stem area is prevented by two O-ring seals and a gland packing. Leakage through the valve body and bonnet connection is also blocked by an O-ring seal and a body gasket. In the event of a fire, O-rings will be melted or decomposed under higher temperature in the fire, then the fire safe body gasket, stem packing will prevent external leakage.

Internal leakage prevention

Internal leakage prevention

In the event of a fire, all none metal materials, like O-rings, soft seats and back rings, will be melted or decomposed under high temperature in

the fire, the edge of metal seat energized by the seat spring will contact with the ball to block the pipeline medium and minimize internal leakage.

Also the fire safe graphite packing is compressed into the seat ring groove to prevent process media leakage through the gap between the valve

body and seat.

Bill of Materials

| no | name of Part | Stainless Steel | carbon Steel |

| 1 | Body End Cap | ASTM A351-CF8M | ASTM A216-WCB |

| 2 | Nut | AISI/ASME 304/GR.8 | Carbon Steel/GR.2H |

| 3 | Body Joint Bolt | AISI/ASME 304/GR.B8 | Carbon Steel/GR.B7 |

| 4 | Body Gasket | PTFE | PTFE |

| 5 | Ball | ASTM A351-CF8M/316 | ASTM A351-CF8M/316 |

| 6 | Seat | PTFE | PTFE |

| 7 | Body | ASTM A351-CF8M | ASTM A216-WCB |

| 8 | Stem | ASTM A276-316 | ASTM A276-316 |

| 9 | Stem Thrustwasher | PTFE | PTFE |

| 10 | Stem Packing | PTFE | PTFE |

| 11 | Gland Flange | ASTM A351-CF8 | ASTM A351-CF8 |

| 12 | Handle Stop | AISI/ASME 304 | AISI/ASME 304 |

| 13 | Snapring | AISI/ASME 420 | AISI/ASME 420 |

| 14 | Handle | Carbon Steel | Carbon Steel |

| 15 | Gland Bolt | AISI/ASME 304 | AISI/ASME 304 |

| 16 | Washer | AISI/ASME 304 | AISI/ASME 304 |

| 17 | Cap Screw | AISI/ASME 304 | AISI/ASME 304 |

| 18 | Anti-static Device | 316SS | 316SS |

note: Additional materials available upon request

Leave your message