GALLERY

PRODUCT DESCRIPTION

T30 Extended Stem Underground Fully Welded Ball Valve

EDVC of fully-welded ball valve adopts forged material, welded body, instead of bolts and nuts, to aviod any potential leakage from body.

The forged body with regular structure and even thickness can avoid shrinkage cavities, pin holes, cracks, sand holes and other defects occurring to casting body valves.

Fully-welded ball valves can be spherical and cylindrical type. Usually the spherical type has only one welding seam on the body, the cylindrical type has two welding seam on the body.

Product Specification:

Size range:2"~48" (DN50~DN1200)

Pressure rating:Class 150~2500(PN16-PN420)

Connection end:Flange,BW

Operation:Manual,Pneumatic,Electric,Hydraulic

Material: Carbon steel,Low temperature steel,Stainless steel etc.

Design Standards:

Design&manufacture according to API6D/ASME B16.34

Face-to-face according to API6D/ASME B16.10

End connection according to ASME B16.5/ASME B16.47/ASME B16.25

Test&inspection according to API6D/API598

Fire safe testing according to API607/API6FA

Features and benefits:

1.Valves are designed with forged steel trunnion mounted.

2.Floating seat.

3.PMSS or metal-metal seat.

4.Balls are fixed by internal mounting plate.

5.Fire safe design as per standard API607 or API6FA.

6.Seat structure could be DBB/DIB/DBB-DIB

7.Weled by typical narrow-gap multi-layer submerged arc welding/

8.Welding seams are inspected by 100% UT and hardness test.

Design Features & Applications

EDVC’s standard ball valves have been designed to API’s highest standards. Complete Split body & Fully welded design offers maximum protection against line pressure and thermal distortion with long life and trouble-free performance.

EDVC is supplying its products to the Crude oil transport and processing, Power engineering, Water supply systems and Process Industries throughout the world.

Seal Feature

EDVC ball valves are produced with spring-loaded seats. This spring load keeps the seat in contact with the ball even in absence of line pressure and makes very efficient seal at low line pressure.As line pressure increases, the seat area creates a piston effect which forces the seat against the ball, therefore a tight seal becomes effective. If the pressure is higher, the force exerted by the seat on the ball is increased by action of the pipeline pressure. Therefore, the higher the line pressure, the greater the piston action.

Self Lubrication

Self lubrication, low friction PTFE is used for trunnion and stem bearings. NYLON or other low friction materials are used for seat inserts. Self lubricating seals and stem bearing give predictable operating torque for the life of the valve.

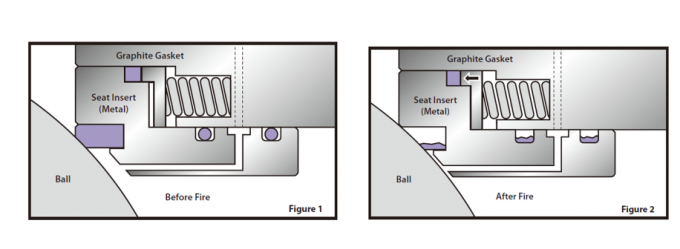

Fire Safe Construction with Secondary Metal Seat

EDVC’s ball valves have been fire tested and can be supplied to API 6FA and API 607. The soft seat inserts, irrespective of their materials, will possibly fail when subjected to sudden high temperature conditions. EDVC provides a fire-safe design which may substantially prevent leakages through seals when damaged by high temperature. The function of the seats before and after the fire test is shown on the sketches. If the seat inserts are destroyed or burned out, a metal to metal seal is formed between the lower diameter of the seat and ball, while the seat to body seals, the stem packing and the end connections to body seals are designed to resist high temperature and will remain undamaged.

(Figures 1 & 2)

Trunnion Mounting

Trunnion mounted stems absorb the thrust from line pressure, preventing excess friction between the ball and seats, so even at full rated working pressure, operating torque stays low.

(Figure 3)

Body Vent and Drain

The body cavity may be vented in both open and closed state.

(Figure 4)

Double Block and Bleed

The seats are of both-side-sealing type, which means that they seal both on the upstream or downstream side of the ball valve and inside the valve. Whether in the open or closed position, pressure on each side of the ball is blocked from the body cavity by the seat rings engineered to self relieve. No pressure build up can occur in to body cavity. The body cavity can then be vented to the atmosphere or drained through the body port.

(Figure 5)

Sealant Fitting

Sealant lubrication fittings come as a standard with EDVC’s design. In the event of seat insert or stem seal damage, external or internal leakage can occur. Emergency sealant injection can save the integrity of the valve by incorporating a sealant seal around the stem or between the seat and the ball until such time the valve may be properly serviced.

(Figures 6, 7 & 8)

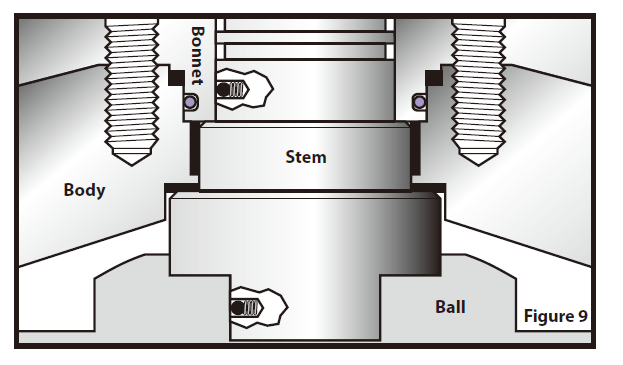

Antistatic Device

The springs provided at the stem allow the static charges to be led to the piping. In this way, an electrostatic charging of the ball is eliminated.

(Figure 9)

Welded Body Construction Ball Valve -Expanded View

| no | name of Part | Materials | |

| 1 | Body | A350 LF2 | A182 F316 |

| 2 | Closure | A350 LF2 | A182 F316, A351, CF8M |

| 3 | Stem | A350 LF2+ENP | 316 SS, 17-4 PHSS, 410 SS |

| 4 | Seat Ring | A350 LF2+ENP | 316 SS, 410 SS |

| 5 | Ball | A350 LF2+ENP | A182F316, A351, CF8M, 410 SS |

| 6 | Seat Insert | Devlon, Nylon, PEEK, RTFE | |

| 7 | Trunnion | A350 LF2 | 316 SS, 410 SS |

| 7-1 | Trunnion Block | A350 LF2 | 316 SS, 410 SS |

| 7-2 | Trunnion Block Pin | 410 SS | 316 SS, 410 SS |

| 8 | Gland | A350 LF2 | 316 SS, 410 SS |

| 9 | Adapter Plate | A350 LF2 | 316 SS, 410 SS |

| 10 | Stem O-ring/ Lipseal | Low Temp HNBR /Viton AED | |

| 11 | Stem O-ring | Low Temp HNBR /Viton AED | |

| 12 | Gland O-ring | Low Temp HNBR /Viton AED | |

| 13 | Seat O-ring/Lipseal | Low Temp HNBR /Viton AED | |

| 14 | Seat Subseal | Low Temp HNBR /Viton AED | |

| 15 | Closure O-ring | Low Temp HNBR /Viton AED | |

| 16 | Trunnion O-ring | Low Temp HNBR /Viton AED | |

| 17 | Backup Ring | PTFE | |

| 18 | Gland Seal | Low Temp HNBR /Viton AED | |

| 19 | Body Seal | Low Temp HNBR /Viton AED | |

| 20 | Trunnion Seal | Low Temp HNBR /Viton AED | |

| 21 | Stem Packing | Graphite | |

| 22 | Seat Spring | Inconel X-750 | |

| 23 | Bearing | PTFE, Carbon Steel | PTFE, 316SS |

| 24 | Thrust Washer | PTFE, Carbon Steel | PTFE, 316SS |

| 25 | Sealant Fitting | Carbon Steel, SS Ball Check | 316SS, SS Ball Check |

| 26 | Socket Bolt | A320 L7M | A193 B8/B8M |

| 27 | Socket Cap Screw | A320 L7M | A193 B8/B8M |

| 28 | Stud Bolt | A320 L7M | A193 B8 |

| 29 | Hex Nut | A194 7M | A194 8 |

| 30 | Grounding Pin | Stainless Steel | |

| 31 | Grounding Spring | Inconel X-750 | |

| 32 | Key | Carbon Steel | Stainless Steel |

| 33 | Dowel Pin | Carbon Steel | Stainless Steel |

| 34 | Relief Plug | Carbon Steel | Stainless Steel |

| 35 | Drain Plug | Carbon Steel | Stainless Steel |

| 36 | Mounting Plate | Carbon Steel | Stainless Steel |

| 37 | Gear Operator | Ductile Iron Case, Carbon Steel Worm Gear | |

| 38 | Hand Wheel | Carbon Steel, Ductile Iron | |

| note: Materials also available in F321, F347, F51, F53, monel, inconel, incolloy and hastelloy. Metal-to-metal seated ball valve designs are available upon request. | |||

note: Additional materials available upon request.

*= Used only in bolted body construction.

Leave your message