GALLERY

PRODUCT DESCRIPTION

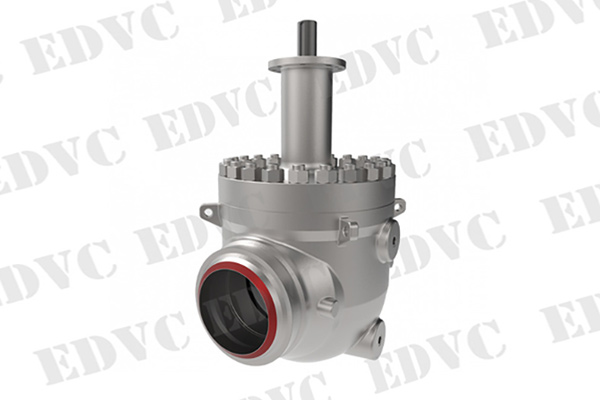

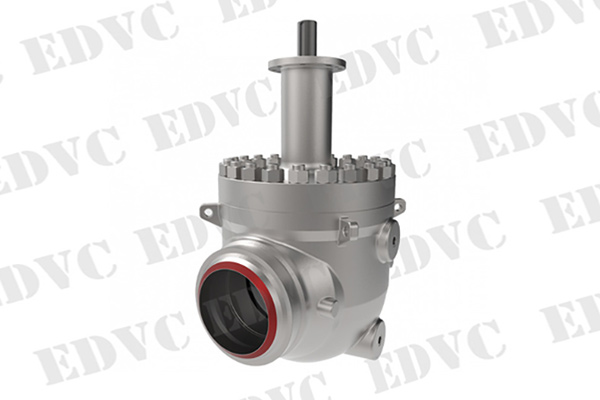

600LB Extended Stem Butt Welded Top Entry Ball Valve

The top-entry ball valve is designed as an integrated valve body. Its support and ball rod fixed by an upper-assembled pivot and an integrated pivot respectively and the integrated high-strength ball rod ensure an accurate ball positioning. The unique technology of retractable valve seat is adopted, realizing online replacement of valve stem, valve stem seal rings, metal valve seats and preloaded springs.

Design Features

The ball valve are designed in accordance with ISO14313,API 6D,BS 5351,GB/T 19672;

Simple structure with good tightness and small torque;

One piece type body;

Have reduce bore and full bore with the minimum flow resistance (zero actually);

Emergency sealant injection;

Cavity pressure self relief;

Low emission packing;

Fire safe, anti-static and anti-blowout stem design;

Valve seat function DBB, DIB-1, DIB-2;

Optional extended bonnet.

Product Range

EDVC’s range of Top Entry ball valves are available in a wide range of materials and configurations to meet your specific requirements. Some options available include;

Body material: carbon steel, stainless steel, alloy steel

Nominal diameter:2"~60"(DN50~DN1500)

End Connection: RF,RTJ,BW

Pressure range:Class150~2500(PN10~PN420)

Working temperature:-46℃~+200℃

Operation : wrench, worm gear, electric, etc.

Designs are of the single piece TOP ENTRY body design with bolted cover engineered for critical service applications combined with true in-line and field maintenance / reparability whilst being designed to withstand severe pipeline stresses.

The double sealing action of the primary o-ring and fully contained graphite seal ensures zero leakage and fire safety assurance irrespective of any pipeline stresses being directed against the rigid single piece body and no intermediate bolted joint as associated with side entry valves. Alternative designs using SWG gaskets is available on request.

Cover bolting calculations satisfy the requirements of ASME B16.34 and in particular allowable bolt stress do not exceed the maximum value of either 7,000 or 9,000 psi respectively whichever bolt material is used.

The design complies with the requirements of ASME B16.34. Other codes (in particular ASME VIII Division 1) are only used as a supplement to ASME B16.34 for additional calculations not already covered in ASME B16.34.

Local weld overlay with corrosion resistant material to critical seal areas.

Sealant injection to seat and / or stem area.

Metal seated or primary metal seat with secondary soft insert.

Transition pup pipes for weld end valves & designs suitable for pigging.

Drain and Vent Connections with thread protection or valved (Gate / Ball…..) vent & drain valve tted.

Pneumatic, Electric or Hydraulic Automation.

Emergency Shut Down applications.

Extended bonnets for low or high temperature service.

Extended stem for underground (buried ) installation.

Locking & interlocking facilities.

Leave your message