GALLERY

PRODUCT DESCRIPTION

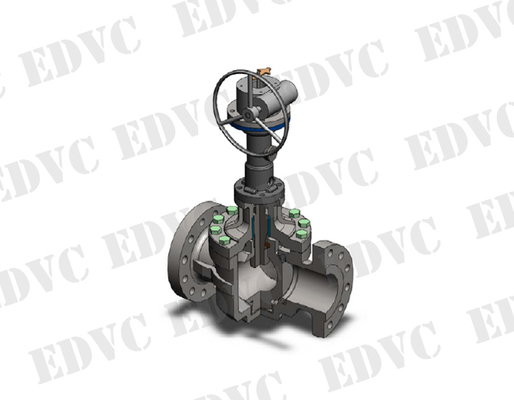

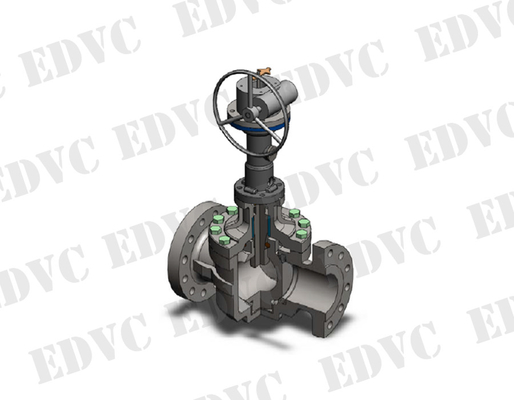

Top Entry Firesafe Design Rising Stem Ball Valve with Drain

EDVC Rising stem ball valve(RBV)) has mechanism to enable dual action and gets sealing by the acting of tilting & turn. Generally, it has low torque prominen tly compared to other ball valves. So, the size of act uator is to be small and our customer can adjust it if there is some leakage in using. Basically 3Z Rising stemem ballball valvevalve iiss pperfecterfect inin sealingsealing. IItt iiss eeasyasy ttoo eexchaxcha nge seat because of top entry type, based on the fiel d situation, and it has long life cycle as there is no friction and abrasion.

The movement of the ball tilted from the seat before starting the rotation eliminates the wear of the seat seal and allows for smooth movement and low torque. The same tilting movement when starting the opening allows for a cleaning flow all around ball surface; this flow automatically flushes the ball surface removing eventual dirt particles from the sealing areas

Product Feature:

- Zero Leakage.

- Low Operation Torque.

- Long life of seat because of no seat abrasion.

- Easy Seat Exchange with Top entry type.

- Protecting seat as there is divided action with dual action.

- Easy and continuous sealing as stem is cam type.

Product Specification:

- Size range: DN50 (2″) to DN600 (24″)

- Pressures range: PN20 (ANSI 150) to PN420 (ANSI 2500)

- Temperature range : -196° to 600°C (-320° to 1112°F)

- End connections : ASME B16.5, Flanged RF, FF, RTJ

Standards:

- Design :API 6D, API 600, ASME B16.34

- Fire Safe : API 607, API 6FA, BS 6755

Features RSBV

Friction Free

An important aspect of the lifetime of a valve is the sealing mechanism. Almost all valves, like Standard Ball, Gate, Plug and Butterfly valves have their sealing mechanism based upon shear force, friction and tearing. The sealing mechanism is based upon axial movement only. The sealing is not liable to friction or tearing. This friction free quarter turn mechanical energised sealing does not generate abrasion on the seal and compared with other types of valves, it results in an exceptionally long lifetime.

Stem design

The stem of the Rising Stem Ball Valve makes only a small axial movement when opening or closing. The stem is always balanced NO stem rotation occurs in combination with axial movement when opening or closing.

Stem Packing

The stem packing of the EDVC Rising Stem Ball Valve can be adjusted while the valve is in service. All valves are executed with a back seat.

Inline maintenance and service

As the valve is designed for easy and low cost maintenance, top-access is possible while the valve is in-line.

Non-slam

The self-locking operate mechanism on all EDVC Valves, provides that the closing member can not rotate due to line forces, therefore there is no danger of line slam, shock or injury of personnel.

Fire Safe

The EDVC valves have been fire safe tested by independent laboratories and have passed the test to BS6755 part 2 and API 6FA successfully. These tests have been witnessed by Lloyds on several valves.

Advantages of the RSBV design

► Friction free opening and closing, increasing the lifetime of the valve.

► Single seat design, no thermal expansion problems.

► Corrosion and wear resistant materials are used on the closure members.

► Self cleaning closure members, due to high velocity flow during opening and closing.

► Top entry design for in-line inspection and maintenance.

► Adjustable stem packing while the valve is in service.

► All valves are executed with a back seat, which gives the possibility to renew the stem packing under pressure

► Mechanically energised sealing, no springs or other weak devices are required to obtain the sealing.

► Non lubricated seal.

► Pressure independent sealing.

► Stem moves only up and down, no rotation.

► No coupling cam in the stem construction

► Topworks according to ISO 5210

Rising Stem Ball Valve applications

Rising Stem Ball Valves are often used in the following applications:

Sand slurry service (special sand slurry design), Lethal (H2S) service (special Bellow Seal design), Produced water service, Steam service, Molecular Sieve service, Dehydration & Regeneration service, Hydrocarbon service, Gas metering, Emergency Blow Down and Shut Down service, Hot Oil service, High Temperature service, Low Temperature service.

Expanded View & Bill of Materials

| Bill of Materials | |||

| no. | Part | WCC | 316ss |

| 1 | Body | A216-WCC | CF8M |

| 2 | Gasket | Graphite+304 | Graphite+304 |

| 3 | Trunnion Bearing | Stainless Steel | |

| 4 | Seat Ring | 410SS | F316 |

| 5 | Seat Insert | PTFE | PTFE |

| 6 | Nut | A194 2H | A193 8M |

| 7 | Stud Bolt | A193 B7 | A193 B8M |

| 8 | Ball | A105+316 | F316+STL |

| 9 | Core Pin | 17 - 4Ph | 17 - 4Ph |

| 10 | Bushing | A276 410 | F316 |

| 11 | Graphite Seal | Graphite | |

| 12 | Packing Rings | Teflon | |

| 13 | Lantern Ring | Stainless Steel | |

| 14 | Stem | A182-F6A | F316+N |

| 15 | Packing Fitting | 316SS | 316SS |

| 16 | Bonnet | A216-WCC | CF8M |

| 17 | Stem Guide | 17 - 4PH | |

| 18 | Bearing | Alloy Steel | |

| 19 | Bearing Race | Alloy Steel | |

| 20 | Drive Nut | Alloy Steel | |

| 21 | Indicator Screw | Alloy Steel | |

| 22 | Handwheel | Cast Steel | |

| 23 | Drive Nut | Alloy Steel | |

| 24 | Set Screw | Carbon Steel | 316SS |

| 25 | Handwheel Nut | Carbon Steel | |

| 26 | Position Indicator | Stainless Steel | |

Leave your message