GALLERY

PRODUCT DESCRIPTION

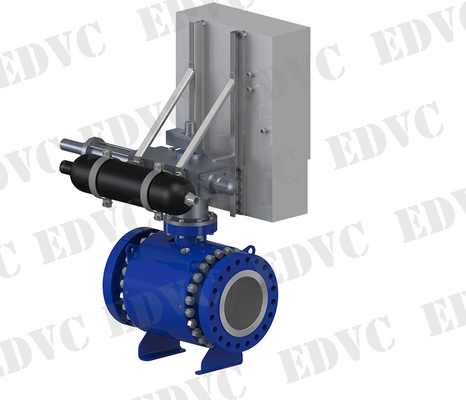

Gas-Over-Oil Actuated Ball valve

The gas over hydraulic actuator is designed and used for the operation of quarter turn valves (ball valves) installed on gas transportation lines, in compressor stations and everywhere a high pressure gas supply is available.

The gas over oil is composed of one or two double action hydraulic cylinders that, pressurized, determine the linear motion of the piston contained in it. The linear motion of the piston is transformed into rotation by a scotch yoke mechanism.

Gas sampled by the line, pressurizes oil contained in one of the two gas-hydraulic tanks and then the one of the cylinder determining the drive of the actuator.

A peculiar feature of gas over oil actuator is its great flexibility of use obtained by the choice of a manufacturing solution easy, solid and without parts in motion.

FEATURE:

Actuators operating at different pressures are available upon request.

Varieties are offered depending on geographical requirements, engineering works and site conditi

Gas over oil tanks separate the feeding gas from the hydraulic cylinder.

Canted or symmetric scotch yoke design achieves high break torque for operating all kinds of quarter-turn valves.

Automatic control groups for the actuator operation (in opening or in closing) are also available. Such as: ON-OFF, Line Break Valve (LBV), Emergency Shut Down (ESD), Electrical Fail Safe (EFS) and Liquid Line Break Valve (LLBV).

TECHNICAL DATA

Design Pressure : Up to 105 barg

Supply Medium : Sweet or Sour high pressure gas, Nitrogen or Instrument Air

Output Torque : Up to 750,000 Nm

Ambit Temperature (Standard Range) : –29°C to +80°C

Ambit Temperature (Extend Range) : –60°C to +180°C

Gas over oil bal valve work with line pressure. They work by compressing hydraulic oil with the supply pressure. They perform perfectly on all quarter turn valves. They are the actuator type that is frequently preferred in natural gas pipelines. Gas over oil actuators can be upgraded with emergency shutdown, fail safe and line break features according to customer requirements.

DOUBLE BLOCK & BLEED (DBB)

EDVC trunnion mounted ball valve seat ring can cut the medium service from upper stream to achieve double block function.

When the ball is fully open or closed position, even the valve is under medium pressure from both side, the body cavity and the pressure is blocked, and the remaining medium service in the cavity can bleed out through the drain hole or vent hole.

CAVITY PRESSURE RELIEF

When the pressure in cavity is increasing abnormally, the single piston effective seat can release the overloaded pressure automatically, while for the double piston effective seat designed ball valves, the overloaded pressure will be released through the automatic pressure relief device installed on the valve body.

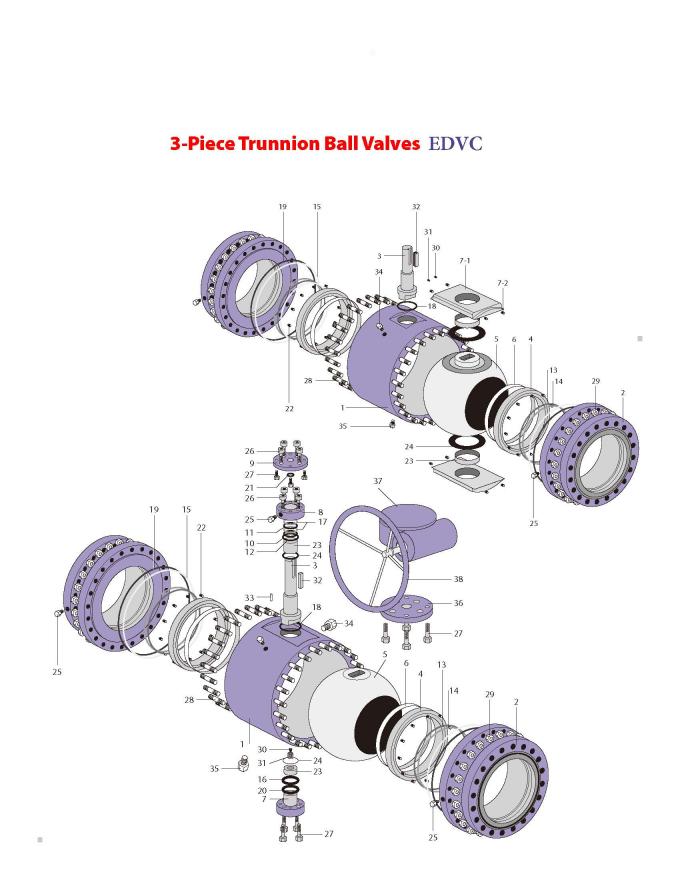

| no | name of Part | Materials | ||

| 1 | Body | 4130 | A182, F316 | |

| 2 | Closure | 4130 | A182, F316, A351, CF8M | |

| 3 | Stem | AISI 1045 ENP, AISI 4140 ENP | AISI 4140 ENP | 316 SS, 17-4 PHSS |

| 4 | Seat Ring | A105 ENP, A106 ENP | A350, LF2 ENP | 316 SS |

| 5 | Ball | A105 ENP | A350, LF2 ENP | A182F316, A351, CF8M |

| 6 | Seat Insert | Nylon, PEEK | ||

| 7 | Trunnion | AISI 1045, AISI 4140 | 316 SS, 410 | |

| 7-1 | Trunnion Block | AISI 1045, AISI 4140 | 316 SS, 410 | |

| 7-2 | Trunnion Block Pin | AISI 410 | 316 SS, 410 | |

| 8 | Gland | AISI 1045 | 316 SS, 410 | |

| 9 | Adapter Plate | AISI 1045 | 316 SS, 410 | |

| 10 | Stem O-ring/ Lipseal | Viton | Viton GLT | Viton |

| 11 | Stem O-ring | Viton | Viton GLT | Viton |

| 12 | Gland O-ring | Viton | Viton GLT | Viton |

| 13 | Seat O-ring/Lipseal | Viton | Viton GLT | Viton |

| 14 | Seat Subseal | Viton, Graphite | Viton GLT, Graphite | Viton, Graphite |

| 15 | Closure O-ring | Viton | Viton GLT | Viton |

| 16 | Trunnion O-ring | Viton | Viton GLT | Viton |

| 17 | Backup Ring | Nylon | ||

| 18 | Gland Seal | Graphite Seal | ||

| 19 | Body Seal | Graphite Seal | ||

| 20 | Trunnion Seal | Graphite Seal | ||

| 21 | Stem Packing | Graphite | ||

| 22 | Seat Spring | Inconel X-750, 17-4 PHSS | ||

| 23 | Bearing | PTFE, Carbon Steel | PTFE, 316SS | |

| 24 | Thrust Washer | PTFE, Carbon Steel | PTFE, 316SS | |

| 25 | Sealant Fitting | Carbon Steel, SS Ball Check | 316SS, SS Ball Check | |

| 26 | Socket Bolt | A574 | 316 SS | |

| 27 | Hex/Socket Bolt | A574 | 316 SS | |

| 28 | Stud Bolt | A193 B7M | A320 L7M | A193 B8 |

| 29 | Hex Nut | A194 2HM | A194 7M | A194 8 |

| 30 | Grounding Pin | Stainless Steel | ||

| 31 | Grounding Spring | Stainless Steel | ||

| 32 | Key | Carbon Steel | Stainless Steel | |

| 33 | Dowel Pin | Carbon Steel | Stainless Steel | |

| 34 | Relief Plug | Carbon Steel | Stainless Steel | |

| 35 | Drain Plug | Carbon Steel | Stainless Steel | |

| 36 | Mounting Plate | Carbon Steel | Stainless Steel | |

| 37 | Gear Operator | Ductile Iron Case, Carbon Steel Worm Gear | ||

| 38 | Hand Wheel | Carbon Steel, Ductile Iron | ||

| note: Materials also available in F321, F347, F51, F53, monel, inconel, incolloy and hastelloy. Metal-to-metal seated ball valve designs are available upon request. | ||||

note: Additional materials available upon request

Leave your message