GALLERY

PRODUCT DESCRIPTION

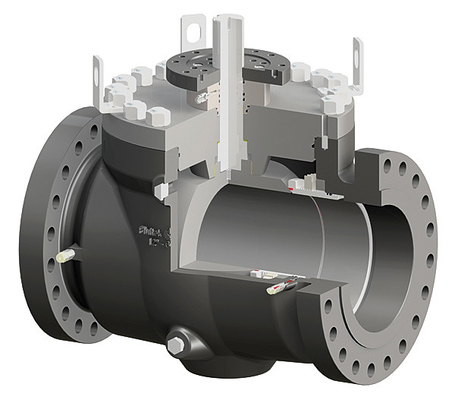

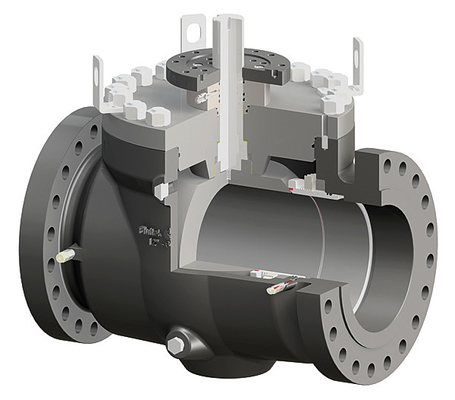

Fully Welded Trunnion Mounted Top Entry Ball Valve

Trunnion Top Entry Ball Valves add, to the main features of Side Entry Type, the possibility to make maintenance without removing the valve from the pipeline. Special tools provided by Fluitek Orsenigo (necessary only for larger sizes) allow the User to remove the trim vertically, from bonnet side. Body raw material can be forging (for smaller sizes) or sand casting (for larger sizes). Wide range of materials: carbon steels, austenitic SS, duplex-superduplex SS, nickel-based alloys.

Valve main technical features include anti blow-out stem and valve seats design available in three different versions:

SPE (Single Piston Effect): the seat is energized by upstream pressure only .

DPE (Double Piston Effect): the seat can be energized by upstream pressure or by body cavity pressure .

DUAL (SPE upstream and DPE downstream): combining the two seat designs explained above, a double barrier can be assured in case of seat sealing failure.

Main reference codes:

Standard design can be in accordance with API 6D / ASME B16.34 / API 6A.

Antistatic design as per API 6D and ISO 17292.

Valve ends can be flanged (RF, FF, MF or FF, RTJ), according to ASME B16.5 (up to 24”) or ASME B16.47 (26” and above), Butt-Welding according to ASME B16.25.

Fire Safe according to BS6755 / API 6FA / API 607, since each sealing point is provided by a secondary fire-safe seal in graphite. Valve soft seats also are provided with secondary metal-to-metal seal in case of fire.

Trunnion ball valves can be manual operated (lever or gearbox depending on valve size), but also equipped with an actuator (electric, pneumatic, hydraulic, gas-over-oil etc.).

Standard design is soft seated and gear operated, the following special designs are also available:

METAL-TO-METAL SEAT: for high temperatures (larger than 250°C) or dirt/slurry service, hard facing on seat and ball contact surfaces (Tungsten or Chromium Carbide).

SUBSEA DESIGN: for subsea applications, Top Entry Ball valves are provided with additional seals, blind nuts, subsea actuators etc. Valve design according to API 6D SS and ISO 14723.

STEM EXTENSION. For special applications the operator (lever/gear/actuator) can be lifted by an extension fixed to valve body, and a joint coupled to the stem.

The following optional features are also available:

Locking device.

Floating ball valves for drain and vent connections (if prescribed by Customer requirements)

Emergency stem seal injection;

Emergency seats sealant injection;

Weld overlay (316 or Inconel 625) on dynamic sealing areas or in all wetted parts.

Certified lifting devices;

Seal welded fittings.

Leave your message