GALLERY

|  |  |

PRODUCT DESCRIPTION

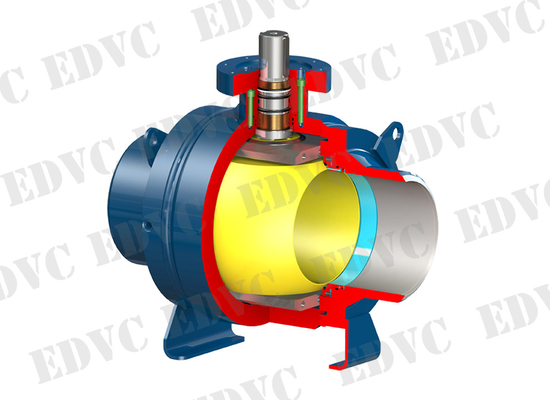

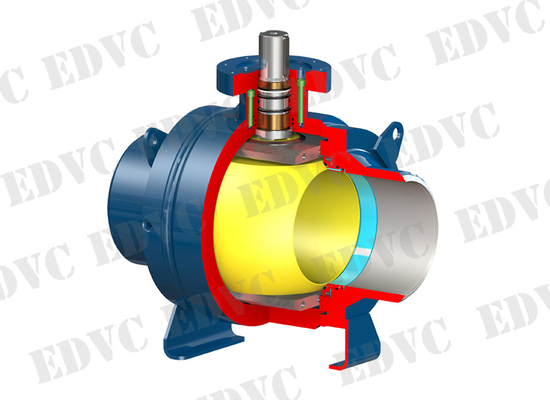

Fully Welded Side Entry Trunnion Mounted Ball Valve

The fully-welded ball valve adopts forged material, welded body, instead of bolts and nuts, to aviod any potential leakage from body.

MAIN FEATURES:

The forged body with regular structure and even thickness can avoid shrinkage cavities, pin holes, cracks, sand holes and other defects occurring to casting body valves.

Fully-welded ball valves can be spherical and cylindrical type. Usually the spherical type has only one welding seam on the body, the cylindrical type has two welding seam on the body.

Product Range:

Body material: low-temperature carbon steel, carbon steel

Nominal diameter:2"~60"(DN50~DN1500)

Pressure range:Class150~2500(PN10~PN420)

End connection: RF, RTJ, BW

Working temperature:-46℃~+200℃

Operation:Wrench, worm gear, electric , pneumatic , gas over oil actuator and electro-hydraulic actuator.

Design Features:

The ball valve are designed in accordance with ISO14313,API 6D;

Simple structure with good tightness and small torque;

With a fully-welded valve body, full bore and the minimum flow resistance (zero actually);

Emergency sealant injection;

Cavity pressure self relief;

Low emission packing;

Fire safe, anti-static and anti-blowout stem design;

Valve seat function DBB, DIB-1, DIB-2;

Optional extended bonnet;

Optional overlay stainless steel on body to seat surface and/or gasket container surface;

Be able to be used for underground installation without corrosion of interior parts, therefore, it is the best application for petroleum and natural gas line systems;

Service life up to 30 years.

Welded body construction eliminates body flanges, reduces potential leak paths and increases

resistance to pipeline pressure and stresses.

Forged steel construction ensures uniform grain structure, toughness and sound weld quality.

Engineered designs and features provide maintenance free performance.

Provides safe and reliable operation to control environmental hazards

BW ball valves are a fully welded body and trunnion mounted ball valve, available in from size 2"to 60" ANSI class from 150 to 2500, temperature range from -46 to 200 . Fire safe conforming to BS 6755 and API 6Fa.

Compared to flanged split body trunnion mounted ball valves, fully welded body valves eliminate the possibility of leakage through the body connection. The fully welded body design is compact, cost-efficient and provides maximum strength and maximum resistance to pipeline pressures and stresses. In order to avoid internal damage caused by heat transfer during installation/welding, the valves are designed with extended weld ends.

The fully welded body ball valve is preferred in applications such as long-distance transport pipelines and under-ground services.

BW fully welded ball valve illustrated cross-section drawing which is only for demonstrating of basic design features, The actual product design may be slightly different from the sample drawing due to size and pressure class.

Leave your message