GALLERY

PRODUCT DESCRIPTION

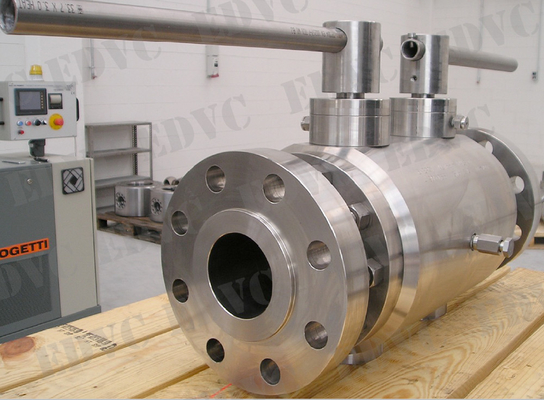

2500LB BW Trunnion Mounted Double Block & Bleed Ball Valve

EDVC double block and bleed valves combine two in-lineisolation valves into a single body with an additional bleedvalve used to drain or vent trapped fluid between the twoobturators to ensure highest level of safety in double isolationand bleed service.

Modular double block and bleed valves combine two in-lineisolation valves into a single body with an additional bleedvalve used to drain or vent trapped fluid between the twoobturators to ensure highest level of safety in double isolationand bleed service.

Several unique features are available to offer advanced Several unique features are available to offer advanced technical solutions suitable to deal with aggressive and severeoffshore environments.Material selection is fully customizableto meet customers project specifications.

Design features:

• Double block and bleed design (DBB).

• Secondary seals in pure Graphite.

• Anti-static device.

• Anti-blowout stem.

• Soft-seated or metal-seated designs with hardfacingon ball and seats.

• Seat configurations available: four self-relieving, fourdouble piston, or combination.

• O-ring/ Lip seal configuration.

• Emergency sealant injection on seats and stem available.

• Low fugitive emission stem packing available.

• CRA overlay on all dynamic sealing areas or on all wettedparts available.

• Extended bonnet for low & high temperature available.

• Low pressure loss through the valve.

• BTC series: extremely compact valve design as per highpressure compact ball valves.

Operator:

• Manual: Wrench or gear with padlocking.

• Actuated: Pneumatic/hydraulic/electric.

Testing & certification:

• Compliance with inspection and testing: API 6D,ISO 5208,and APl 598 or API 6A or API 6DSS.

• Fire safe and fire tested as per API 6FA/607.

• SIL 3Certification as per lEC 61508.

• Fugitive emission as per ISO 15848.

• PED 2014/68/UE.

• Available as per API 6A:

Product specification levels PSL 1,2,3,3G, and 4.

Performance requirement levels PR1,PR2.

Design validation as per PR2F.

DESIGN, CONSTRUCTION, MARKING FOR DOUBLE BLOCK & BLEED VALVES

PRODUCT OVERVIEW

manufactures the most complete line of quality Double Block & Bleed valves, and can provide the exact Double Block & Bleed valves and actuators to meet the most demanding application requirements.

Our Double Block & Bleed valves are available in an extensive range of designs, materials, sizes and pressure classes and are in full con- formance with ASME, API and NACE specifica- tions.

All Double Block & Bleed valves are designed in accordance with ASME B16.34 and where applicable with API 6D or BS EN ISO 17292.

The EDVC family of Double Block & Bleed valves provides positive shut-off of fluids and gases under extreme service conditions.

EDVC uses only high-quality materials inspected & tested to International Standards and uti-lizes advanced manufacturing technology with special emphasis on safety, quality, and long service life of our products, to ensure that our clients receive the “best in class” products available from us at a competitive price and delivered on time.

The forging material can ensure the best rigid- ity and strength under maximum rated opera- tion pressure without inherent flaw of cast. Other properties found in forging include greater impact resistance, resistance to fatigue cracking, particularly when cycling at either high or cryogenic temperature. Overdesigned wall thickness and adaptation of high strength tie bolts are convenient for valve maintenance and sufficient to bear the stress of pipe.

The internal parts of valve are carefully de- signed and selected to ensure reliability under all kinds of work conditions.

Since a variety of materials are available, EDVC valves can be used with various fluids and gas-es including petroleum based oils and some water glycols.

EDVC Double Block & Bleed Valve design is developed using the latest software based analysis tools.

At the design stage, all projects are analysed using 3D solid modeling tools.

Benefits include reduction of development time and costs, improved product quality, and ability to solve field problems for customers. Product flexibility and accuracy is assured.

Finite Element Analysis (FEA) is a very important step of the development stage and ensures the best possible performance requirements. Valves operational problems, pressure/temperaturerelated deformations and flow-related forces within a valve can be evaluated.

EDVC uses the FEA for predicting failure due to unknown stresses by showing problem areas in a material and allowing designers to see all

of the theoretical stresses within. This method of product design and testing is far superior to the manufacturing costs which would accrue if each sample was actually built and tested.

During any analysis project, it is the responsi- bility of the EDVC analyst to verify that analysis results conform to the physics of the problem under study. Understanding the response of a structure or manufactured product allows effective design decisions to be made in de-veloping structures and products that are func-tional, meet all engineering requirements, and can be manufactured and assembled.

Computational Fluid Dynamics (CFD) is used to simulate operating flow conditions. Evaluation of Valve CV coefficient and convec-tive heat transfer coefficient takes place at the design stage.

MAIN FEATURES

Fire-Safe Test approved

EDVC Double Block & Bleed valves are designed in accrdance with API 607 & API SPEC 6FA.

double body Gasket

All EDVC Double Block & Bleed valves are equipped with two body gasket. The first body gasket is in soft material and the second in graphite (if not otherwise required), this com- bination assures the best seal characteristic in whatever corrosive service as well as giving a fire safe design.

anti-Static device

In order to prevent static electricity which may light the fluid, static-conduction spring is set between the stem and the ball.

anti blow-out prooF Stem

The stem is designed with integral T-Type shoulder to provide blow-out proof effectively. The design assures that the stem can not be blown out of the valve in the case of the pack- ing being removed while the valve is under pressure.

controlled Stem & Stuffing box Finish Stem and stuffing box finish machining is a key point of control. The stem is made by cold rolling and stem surface finish is controlled by Ra=0.4, which can reduce friction of stem movement and ensure the seal. The stuffing box surface is controlled within Ra=1.6 for bet- ter sealing performance.

Solid ball

The solid ball used by EDVC provides straight-through flow and real full-port performance characteristics. Hollow ball or cored cavity ball are not used for EDVC products.

longevity of life

Special consideration was devoted to the at- tainment of enhanced life and operation of our valve throughout design, development, testing and manufacturing stages.

Valve designs combined with the selection of advanced materials are such that long periods of inactivity should not affect the operations of efficiency.

low torque output

Seat designs, stem-bearing system and stem seal arrangements ensure consistent minimal torque values.

Leave your message